How to Select Injection Molding Services in China

So, the big meeting just wrapped up. your new project has the green light, the timeline is aggressive, and the budget is, let’s say, constrained.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. Savings can be substantial. Yet your thoughts are already spinning. You’ve heard all the horror stories, right? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

However, here’s the reality. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

First Things First: Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This becomes the bedrock of your sourcing project.

So, what goes in it?

First, your 3D CAD files. They’re essential. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the authoritative CAD geometry.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. Here you specify what 3D can’t show. Think tolerances, material grades, finish specs, and any feature-critical notes. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Don’t just say “Plastic.” Nor just “ABS.” Get precise. Call out SABIC Cycolac MG38 (black), for example. Why so detailed? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. State your EAU. They need clarity: is it 1,000 total shots or a million units per annum? Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

Okay, your RFQ package is a work of art. who will you target? Online sourcing is global but crowded. Finding suppliers is simple; finding quality ones is tough.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They let you survey dozens of suppliers quickly. Treat them as initial research tools, not final solutions. Aim for a preliminary list of 10–15 potential partners.

Still, you must dig deeper. Consider using a sourcing agent. True, they charge a fee. But a good one has a vetted network of factories they trust. They are your person on the ground, navigating the language and cultural barriers. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Consult trusted colleagues. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. estimates roll in. Some prices will undercut logic, others will shock you. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How to proceed? It involves both metrics and gut feel.

First, look at their communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Get their tooling inventory. Review examples of parts akin to your design. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. You can’t skip this. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

You’ve selected your partner. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

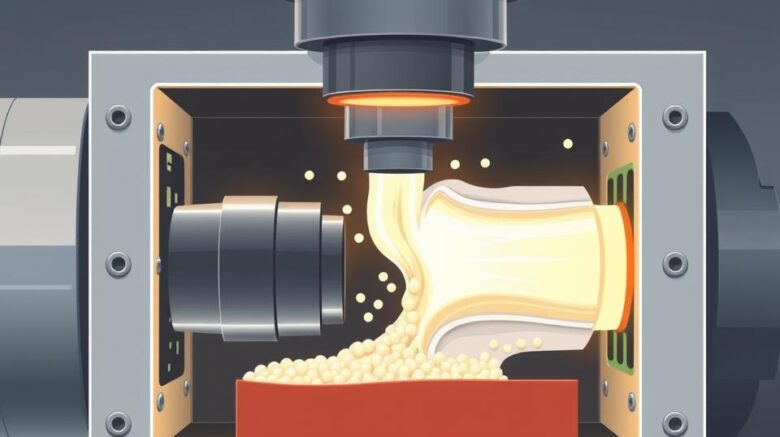

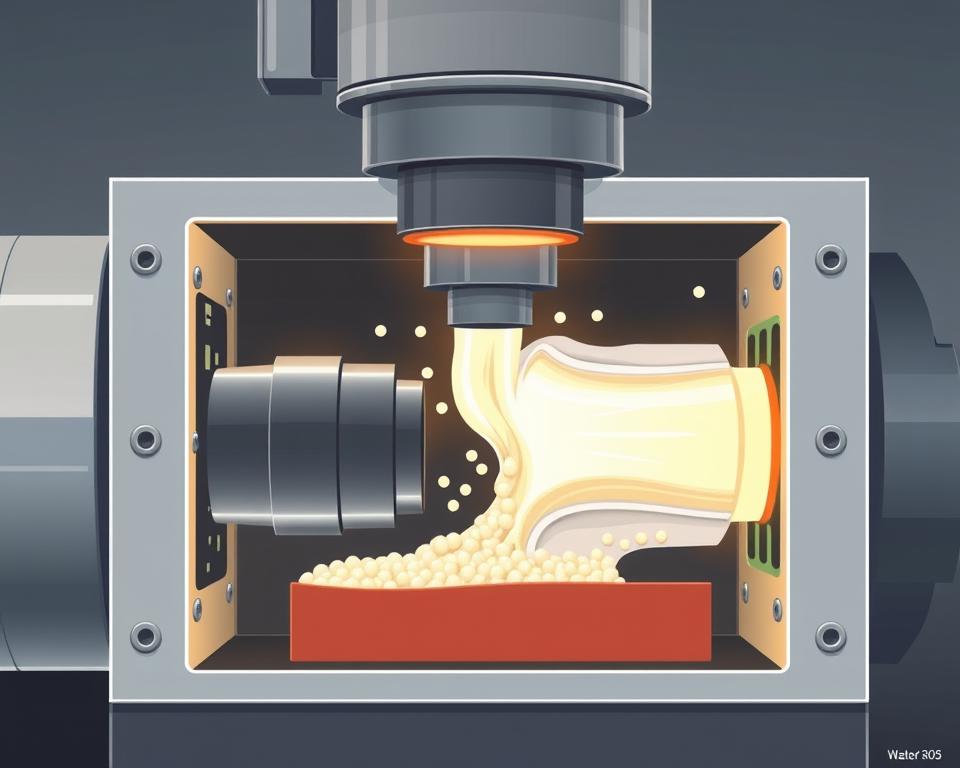

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. Together, you tweak the design for best manufacturability.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. It’s your test of success.

T1 parts usually require adjustments. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. You may repeat this cycle a few times. Plan for this loop in your schedule.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Now comes full-scale production. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This audit shields you from mass defects.

Lastly, plan logistics. Understand the shipping terms, or Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.